John Wolff's Web Museum

Rebuilding the Model 3D11 Comptometer

Contents

|

|

| Comptometer 3D11, c.1955 |

Introduction

These notes give a detailed step-by-step procedure for a complete

disassembly, reassembly, and adjustment of the Felt & Tarrant Model 3D11

manually-operated Comptometer. A separate procedure is provided for

rebuilding the earlier Model J. Readers with a Model H should use the

Model J procedure; those with a Model M or WM should adapt the relevant

sections from each procedure.

The notes have been prepared and refined during the rebuilding of

a significant number of Felt & Tarrant machines of various types.

There are no particular difficulties in rebuilding a Comptometer, and

there is no requirement for workshop facilities or special tools.

However it does require patience, care, and attention to detail. The

procedure following works well for me, but comes with no guarantees.

No responsibility will be taken for any consequences arising from

the use of these notes by others.

The notes are intended to be read in conjunction with the

Technical Description of the Model J

Comptometer, and with the more general information in the

Notes on overhauling a mechanical

calculator. The Technical Description explains the construction

and operation of the basic Comptometer mechanism and illustrates all of

the major components and assemblies, while the Notes on Overhaul describe

more general techniques for disassembly, cleaning, and rebuilding. Please

study this material carefully before commencing your overhaul, and

refer back frequently for the illustrations as you proceed.

I would be happy to receive feedback, comments, or suggestions via

the enquiry form.

Disassembly

Disassembly does not require any special tools, although a good

pair of bent-nose tweezers or fine pliers will be found useful. Except

where advised otherwise, it is strongly recomended that you keep the

parts in column order during disassembly and cleaning. The extra time

taken will be saved many times over by avoiding trouble in reassembly

and adjustment. Accumulators, for example, were selected in the factory

according to the angular (mis-)alignment between the pinion and the

accumulator gear, and may cause significant problems if paired

incorrectly. Keeping columns together is especially important in

non-decimal machines, where many similar components have small

differences but big incompatibilities.

A Comptometer can be disassembled to frame level in about 3 to 4

hours if no problems are encountered. A thoroughly gummed cross-shaft

can take 4 hours on its own.

Please review the material in the

Notes on overhauling a mechanical

calculator, and proceed as follows:

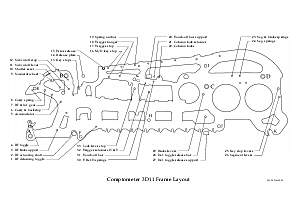

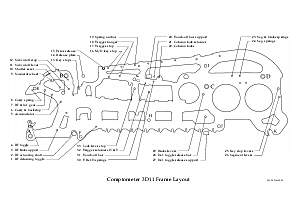

- Preliminaries

- Print a copy of these notes, and tick off each step as it is

completed.

- Print the

frame plate outline drawing (PDF file, 64kb) to show the location

of the 33 mechanism cross-shafts.

- Prepare a set of numbered bags or containers to receive the parts

in column order, and to store the cleaned parts. Column 1 is on the

right. Prepare containers labelled A to K to receive the frame

tie rods, spacers, and shims.

- Unscrew and remove the top of the clearing handle. Pull off the

error release button (front) and the Mul/Div button (left). The

buttons are retained by spring-loaded ball catches which may be

stuck or rusted.

- Stand the machine on its left-hand side and remove the small

screws around the edge of the baseplate. Some of these screws will

probably be missing, as they tend to work loose and fall out. Set

the machine back on its feet and lift off the cover.

- Invert the machine and set the keys down on a soft cloth. Do not

roll it over, as this can break the keytops. Remove the 4 screws

through the rubber feet and lift the baseplate away from the mechanism.

Set the machine back on its internal feet.

- Remove the cross-shaft retainer plates (metal or fibre-board)

from the sides of the mechanism (3 screws each side).

- The rock frame.

- Clear the machine. From the right-hand side, push the intermediate

gear shaft 7 to the left to clear the shutter actuating lever in the

rightmost column (shown on the left in the photo opposite), but not so

far as to release the intermediate gear. The shutter actuating lever

has a long invisible arm on the left-hand side with a roller at the

bottom. Tilt the lever so that the roller moves rearwards, then

upwards, then forward, then lift it out in front of the hub of the

intermediate gear. If the roller catches on the carry gear and will

not move upwards, it can be released by turning the numeral wheel

slightly.

- Withdraw shaft 7 further and drop the intermediate gear down into

the space between the large carry gear and the frame plate to its

right. The top of the gear should be just below the top of the rock

frame plate.

- Lift out the subtraction cutoff latch release lever (on the right

in the photo). The top end of this lever is hidden between the numeral

wheel and the frame plate to its right. The lower end has a fork which

fits over a wire in the rock frame, just below its top spacer rod.

Pull the bridge of the lever forward, ease the top arm past the

shutter operating tab, and lift out.

- Repeat the process in the remaining columns. Insert a short

temporary pin (eg the shank of a 7/64" drill) at the right-hand end

to support the rock frame as wire 7 is withdrawn. Leave wire 7 in place

to support the frame at the left-hand side. (If you have the

facilities, it is convenient to make up a couple of short temporary

pins of 7/64" (0.108") diameter to support the rock frame during

removal and reinstallation).

- Release the clip at the right-hand end of the rock frame toggle

pivot wire 4. Pull the rock frame forward, withdraw the wire to the

right, and recover the helper springs.

- Press any key to release the detaining toggle. Lift the front of

the machine and remove the support wire 3 which passes through the

slots in the rock frame actuating links. Pull the rock frame forward

and disengage the forked links from the pins on the rock frame plates.

Place a suitable block under the front of the machine so as not to

damage the links when putting the machine back down.

-

Support the rock frame with one hand and remove wire 7 and the

temporary pin. Hold the rock frame at each end, lift it straight up as

far as it will go, and pull it forwards to clear the duplex levers.

Rotate the frame until the two locating flanges (top centre) are clear

of the main frame plates, then push it across to the right. The

movement is only about 1mm, just enough for the toggle levers to

clear the toggle link rivets. Sit the leftmost escapement lever over

the toggle link mounting point, as illustrated, then swing the top of

the rock frame forward so that it passes under the top spacer bar E.

Lift out carefully to avoid catching on the carry levers. Although it

may seem impossible at first, the rock frame can actually be removed

and replaced quite easily after a bit of practice (and you'll get

plenty of practice by the time you've finished). It is never necessary

to use force, to remove the tie rod, or to modify any part of the

machine.

Support the rock frame with one hand and remove wire 7 and the

temporary pin. Hold the rock frame at each end, lift it straight up as

far as it will go, and pull it forwards to clear the duplex levers.

Rotate the frame until the two locating flanges (top centre) are clear

of the main frame plates, then push it across to the right. The

movement is only about 1mm, just enough for the toggle levers to

clear the toggle link rivets. Sit the leftmost escapement lever over

the toggle link mounting point, as illustrated, then swing the top of

the rock frame forward so that it passes under the top spacer bar E.

Lift out carefully to avoid catching on the carry levers. Although it

may seem impossible at first, the rock frame can actually be removed

and replaced quite easily after a bit of practice (and you'll get

plenty of practice by the time you've finished). It is never necessary

to use force, to remove the tie rod, or to modify any part of the

machine.

- Lift out the intermediate gears and put the rock frame assembly

aside for later.

- The numeral wheels and accumulators.

- Starting from the right-hand side, unhook the forward end of the

stiff spring between the subtraction cutoff lever and its latching

lever. The latching lever is part of the shutter assembly, and the

spring is just below the numeral wheel shaft 9. Use a pair of fine

pliers to turn and unhook the spring to avoid deforming the loop.

- Withdraw the numeral wheel shaft 9 one column to the left and

remove the numeral wheel and shutter assembly towards the front. (Push

the curved shutter reset link out of the way if necessary). Continue

to the end.

- Loosen the screw at the right-hand side of the top front spacer

bar E. Push the front lip of the spacers down just enough to free the

carry lever spring retainer wire 8. Withdraw the wire and release

the springs.

- Note the location of the accumulator backstops and their torsion

springs on wire 6 at the right of each column. Raise the front of

the machine and carefully unhook the bottoms of the springs where they

pass over the frame plate.

- Withdraw the backstop wire 6 gradually to the left and remove the

backstop and spring, the carry lever assembly, and the accumulator

latch lifter (between the arms of the carry lever). Note that column

1 has a stronger backstop spring.

- Withdraw the accumulator wire 5 to the left and remove the

accumulators.

- Lift the clip at the left-hand end of the shutter reset wire 10

and withdraw the wire to the left. Remove the curved links. Disconnect

the lower links from the pins on the rock frame actuator bell cranks

(under) and lift out.

- The right-hand support plate.

- Stand the machine on its back, with a suitable support to stop

it falling backwards. Note the arrangement of the links on each end

of the detaining toggle release bar 28. Lift the clip at the

left-hand end and withdraw the bar to the left, releasing the

links on both sides.

- Follow the detaining toggle release link in the left-hand column

up to the detaining toggle pivot assembly. Unhook the left-hand spring

(4mm) from the tab on the frame plate.

- Follow the detaining toggle links from the pivot assembly to the

pinned arm on the rock frame actuating shaft 2. The toggle link is

held in place by a slotted link attached to a long 5mm spring. The

link has a tapered slot which fits into a groove in the pin. Grasp the

link with a hook or pliers, pull it forward, and release it from the

pin. Push the detaining toggle link off the pin.

- Stand the machine on its left-hand side. Remove all the screws

from the right-hand support plate, then ease the plate off the ends

of the tie rods. Lift out the large L-lever and rearward link. Recover

6 round spacers, including the thin-walled spacer inside the hub

of the L-lever.

- Rotate the detaining toggle release bar support 27 half a turn

to free the arms and lift out.

- Lift out the rock frame actuating shaft 2.

- Stand the machine on its back and remove tie rod F and spacers.

Note the special grooved spacer under the detaining toggle at the

left-hand side, and the rock frame actuating shaft support bracket

and its short spacer near the centre. It is not necessary to keep

the plain spacers in column order.

- Spread the two leftmost frame plates and carefully extract the

detaining toggle assembly from its bearings.

- Disassemble the clearing handle mechanism on the support plate

and set aside.

- The keys and keyplate.

- Stand the machine on its back, with a suitable support to stop it

falling backwards.

- If you have the facilities, measure the wire diameter of the

keypiece springs and determine whether they are all the same or

graduated by row. (3D11 springs are usually graduated in 4 steps from

front to rear). If graduated, record the diameter for each row and

prepare containers for each size to avoid sorting later. Otherwise,

prepare separate containers for the springs from rows 1 to 9.

- Remove the keypieces, starting at the top right. Put on your safety

glasses, place a finger firmly over the coil of the spring (in case it

flies), and unhook the tail of the spring from the frame plate. Twist

the keypiece to the right, release it from the key, and remove the

spring. Work from right to left, then down, one full row at a time.

The keypieces were all identical when new, but may have been

"formed" or adjusted in service. The arms are easily re-adjusted,

so they can all be stored in the same container. In Sterling machines

it is necessary to fully depress the adjacent segment levers in order

to remove the 10 and 11 keypieces.

- Put the machine back on its feet and lift the keys straight up

and out. Start at the front and work backwards in each column. The

keystems are often tight as the two operating shoulders pass through

the keyplate. Pull on the metal stem, not on the moulded keytop. The

step near the bottom of the keystems will often catch on the keystop

levers and prevent removal, especially on the 10 and 11 pence keys.

Insert a screwdriver from underneath and push the long levers apart to

provide clearance. Keep all the pence keys together as they have

different numbering to the decimal keys (as does the 1 key in the 10/-

column). Stand the machine on its back to investigate any problems.

- Locate the keyplate retainer wires. There are two wires with

right-angled ends on the left-hand side of the machine, in line with

the two notches in the top of the outer frame plate, and another at

the right-hand rear on Sterling (or ex-Sterling) machines. Pull out

the wires and lift off the keyplate.

- Disengage the pin at the left-hand end of the release plate 14

from the forked end of the Mul/Div lever, unhook the spring to the

keystop wire 13, and lift out the release plate.

- Note the arrangement holding the error release lever 15. Early

models have 2 long wires 16 and 19, a clip over wire 16, and a coil

spring to the key stop wire 13. Later models have 2 short crimped

wires, 2 circlips around 15, and a torsion spring around 16. Remove

the front wire 16 and the clip or circlips, align the grooves in 15

with the slots in the frame plates, and lift out.

- Withdraw the trigger stop wire 17 and the spring anchor wire 19.

- Push the trigger hanger wire 18 one place to the right and lift

out the touch-off bar latch release lever from the leftmost (overflow)

column.

- Remove the screw and short spacer at the left of tie rod G. Push

the tie rod to the right and remove the Mul/Div lever assembly and the

frame spacer which acts as a pivot.

- Push the lock lever stop wire 33 one place to the right and lift

out the touch-off bar latch lever.

- Push wires 18 and 33 and tie rod G back into position.

- The key stops and accumulator interlocks.

- Prop the machine up on its back and disconnect all of the long

key stop springs from the inaccessible tabs on the side plates. Use

two hooks or dental picks, one to push or pull the body of the

spring into a suitable position, and one to unhook the spring without

deforming the loop. Try not to think about how you are going to get

these back on later.

- Set the machine back down. Unhook the tops of all the tiny springs

between the accumulator locking hook (ALH) and the pinion ratchet

reverse lock (PRRL). The springs are at the top front, just below

tie rod B.

- Withdraw wires 11, 12, and 13 to the left until clear of the

right-hand column.

- Disengage the hook and tabs at the rear of the upper key stop and

lift out. Disengage the lower key stop, turn it 90° to the left

and lift out. Remove the ALH, PRRL, and the accumulator latch. Withdraw

the wires further, lift the subtraction cutoff lever up, across to the

right, then out. Repeat to the end.

- The trigger mechanism.

- Stand the machine on its back and unhook all the segment lever

springs. In Sterling or non-decimal machines, record the variations

in length, outside diameter, and wire diameter, or label the springs

so that they can be returned exactly to their original positions.

Withdraw wires 23 and 24 and remove the springs. (This also releases

the brake springs).

- Withdraw wire 29 and remove the brake levers.

- Lift the clip at the left-hand end of column lock retainer wire

21 and withdraw to the left.

- Withdraw the column lock pivot wire 22 and remove the

locking hooks.

- Withdraw the thin crimped wire 30 to the right to drop the

springs from the trigger retainers horizontal (TRetH).

- Lift the clip at the left-hand end of the 1/16" square touch-off

bar 31 and withdraw to the left.

- Detach the spring from the left-hand end of the touch-off bar

support 20. Push wire 32 to the right to clear the left-hand arm

on the touch-off bar support. Spread the outer frame plates to

disengage the pivots, then rotate the bar so that the arms align

with the frame cutouts and withdraw to the left.

- Unhook the small springs from the trigger retainer vertical

(TRetV, at the left of each column on wire 32) to the tabs on the

frame plates.

- Withdraw wire 32 to the left and remove TRetH and V.

- Remove tie rod G and the remaining spacers.

- From the rear, unhook the rear of the springs from the segment

lever bell crank to the trigger connecting link and push the links

off the pivot pins.

- From the front, withdraw stop wire 33 one place to the left to

release the touch-off bar latching lever. Push the latching lever

spring off the plain pin on the frame plate and remove the lever.

Withdraw wire 18 one place to the left and remove the trigger assembly

towards the front. Repeat to the end.

- The segment levers.

- Remove the left-hand screws in the bottom rear frame tie rods

J and K. Invert the frame and lift the two internal feet away from

tie rod J. (The feet have slots at the forward ends). Spread the

left-hand support plate to clear tie rod K, then lift the tie

rod, spacers, and feet out of the "U"-shaped slots in the frame

plates.

- Withdraw the key stop lever pivot shaft 25 and remove the pairs

of levers together through the rear of the machine.

- Withdraw the segment lever pivot shaft 26 and remove the segment

and lock levers together through the rear of the machine. Detach the

long spring from the bell crank. Turn the bell crank forward across

the lock lever, then turn the lock lever 90° and separate it

from the segment lever.

- The frame.

- Number the frame plates before disassembly, or devise a method

of keeping them in order. There are many subtle differences that can

easily escape notice, especially in the earlier machines. Take note

of the narrow end spacers between the frame and the outer support

plates. Proceed carefully so as not to bend or distort the plates.

- The rock frame.

- Prepare another set of numbered bags to receive the rock frame

parts in column order, or re-use the first dirty set after cleaning

their contents.

- Open the hinged retainer plates at each of the rock frame.

- Withdraw the locking dog stop wire.

- Hold the first carry gear, spring, and escapement wheel together.

Withdraw the carry gear pivot wire one place and lift out the three

components together. Release the spring tension carefully, check how

far the escapement wheel turns, and record any variations. The initial

preload on the 3D11 was 1.5 turns, but after 80 years it is usually

only about 1 turn. The springs and pre-loads will be different in

non-decimal columns. Separate the parts and store in column order.

Repeat for the remaining columns.

- Turn the frame over, withdraw the escapement lever pivot wires,

and remove the linked escapement levers. The links are intended

to be fairly loose.

- Withdraw the toggle lever pivot wire and remove the toggle levers

and zero stops.

- Make a detailed map of the position of the flanged locating spacers,

tie rods, end plates, and especially the arrangement of the short

spacers, screws and washers at the ends, then disassemble the frame.

The frame plates are all identical (except for the rightmost, which

has no locking dog) and do not need to be kept in order.

Cleaning

Please review the general information about cleaning and checking

in the Notes on overhauling a

mechanical calculator, and proceed as described. Use a large

flat-bottomed dish for washing, and be very careful not to bend the

long levers or the frame plates. Initial cleaning all of the

disassembled parts will take about 6-8 hours.

Reassembly

Please review the material on Reassembly in the

Notes on overhauling a mechanical

calculator. No special tools are required, but you will need to

make some simple spring hooks from suitable fine wire. A pair of

strong locking tweezers (or a surgical artery clamp) will be useful

for holding some of the small parts securely during assembly.

Several mechanism wires have retaining grooves which engage with

flat spring clips. The clips and grooves are made in matched pairs of

several different widths so that the correct wire can easily be found.

Temporary follow-through wires can be cut from silver steel or "music

wire" of 0.0625", 0.088", and 0.108" diameter from an engineering or

hobby supply shop.

In the notes following, tension springs listed as (eg) 3x10x0.3 are

3mm diameter, 10mm closed coil length, and 0.3mm wire diameter.

All parts must be checked thoroughly and lubricated sparingly

during assembly. Apply a thin film of oil to steel parts with a

(slightly) oily rag to help prevent rust, and apply light oil to all

gears, rollers, pivots and bearings.

Reassembly requires patience, care, and attention to detail. If

everything goes according to plan, it will take at least 14 hours to

prepare and check the washed parts and to reassemble and test

the machine.

- The frame.

- Check the threads and the threaded spacer nuts on the large tie

rods A, B, C, and D. These rods have both internal and external

threads, and the surrounding material is often distorted. Ease the

end diameter and/or the thread profile until the both ends will pass

without difficulty through the close-fitting holes in the frame

plates, and the nuts can be run fully down by hand. Note that the

nuts are counter-bored on the inner face to ensure that the rightmost

frame plate is located clear of the threaded section.

- Fit screws and washers to the plain ends of three tie rods A, C,

and D and insert them into the the left-hand support plate. Lay the

plate flat on the bench and assemble the frame plates and plain spacers

in order. Late models with the flat support plate start with 0.210"

spacers on the left-hand side. Early models with the offset front

section have no short spacers at the left of the main tie rods. Fit

the two special formed spacers to rod A in the third or fourth column

from each end, with the small hole for the rock frame helper springs

towards the rear.

- Fit the special nuts and firm up gradually. Adjust the left-hand

screws as necessary to leave about 2mm of the rod showing above the

nut when the frame is tight.

- Place the right-hand support plate in position over the ends of

the tie rods. Check that the ends of the rods are level with or just

slightly above the surface of the plate, and correct if necessary. (If

the rods extend more than the thickness of the washer it will be

impossible to tighten the right-hand side). Temporarily fit the

3 screws and washers.

- Place the frame on a flat surface and check that everything is

true and square.

- Check that the intermediate gear wire 7 (0.108") passes easily

through the holes in the frame plates. Correct any tight spots

by feeding a 7/64" drill bit in from the end and easing the hole on

the side flutes of the drill. The wire should be free but not loose.

- Long levers.

- Check the three rollers on the segment and lock levers and ensure

that they are free. Proceed carefully if they are stuck, so as not to

loosen the pivot pins. Freeing these rollers is very important, and

can take a long time.

- Assemble the pairs of segment and lock levers, attach the bell

crank springs, and install from the rear. Insert the lower pivot

wire 26 (0.108").

- Fit the pairs of key stop levers from the rear, passing them

between the two arms of the segment lever bell crank. Locate them

sideways at the rear by arranging the two short arms on opposite sides

of the adjacent frame plate (ie, the outer lever wraps around onto the

far side of the frame). Insert the upper pivot wire 25 (0.108").

- Before lifting the frame off the bench, lift the levers and insert

any suitable wire through the holes for tie rod F. This will provide

a temporary stop to prevent the levers falling through and becoming

tangled or damaged.

- Trigger installation.

- Refer to the Model J pages for a

description of the standard trigger operation. In the 3D11, the column

lock retainer bar has been deleted, and the locks have been modified to

follow the position of the touch-off bar directly. The locks are

engaged when the bar is pushed rearward, and released when it returns

forward. When the bar is pushed rearward in response to a short

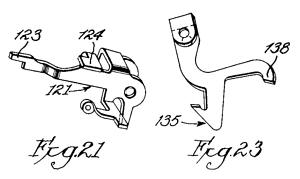

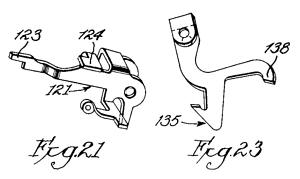

keystroke, a latching lever (Fig.21) drops and holds it in position

via the notch at 123. The latch keeps the rest of the keyboard locked

while the trigger is re-armed to complete the short keystroke. When the

trigger is disarmed at the end of the downstroke, it lifts the latch

via tab 124 and thus automatically releases the touch-off bar and the

column locks. When the Mul/Div control is set for Add mode, an

additional master latch (in the leftmost column) holds the touch-off

bar until released manually by the push-button.

- Prepare plain wires 17 and 18 (both 0.088"), 32 (0.0625"), and

33 (0.108"); crimped wire 30 (0.055"); and tie rod G with

plain spacers.

- Prepare the trigger assembly, trigger retainers H and V, and the

touch-off bar latching lever (Fig.21) for the leftmost key column.

- Grasp the latching lever with pliers or tweezers and hold it in

its approximate position near the centre of the column. The lever

pivots on wire 33, with the long arm facing rearwards. Push the loop

of its spring fully on to the plain pin on the frame plate to its

left. Insert the pivot wire 33 (ie, the lock lever stop wire, 0.108")

from the left.

- Place the trigger assembly in position. The pinned end with the

spring faces forward. The rear end initially passes above the

latching lever and the long connecting link passes below. Ensure that

the rear end of the link lies between the segment lever bell crank and

the frame to its left, and is not caught in any of the cut-outs in the

frame plates. Insert the trigger hanger pivot wire 18 (0.088")

from the left.

- Ease the rear arm of the trigger to the left and tuck it under the

tab 124 on the left of the touch-off bar latching lever.

- Start wire 32 (0.0625") from the left. Place the trigger retainer

vertical (TRetV, Fig.23) against the left-hand frame plate, with the

curved end 138 forward between the trigger and the latch, and resting

on top of wire 33. The hooked end 135 must be in front of the

corresponding tab on the rear trigger arm. Feed in pivot wire 32

until flush.

- Fit the trigger retainer horizontal to the right of TRetV. The arms

face forward, with the right-hand offset arm passing throught the

cutout and to the right of the frame. The left arm sits above the

vertical arm of the trigger. Feed in pivot wire 32 to retain.

- Repeat for the remaining columns, then insert the trigger

stop wire 17 (0.088").

- Connect the springs from TRetV to the tabs on the frame plates.

- From the rear, insert wire 30 (0.055", crimped at right-hand side)

and attach the springs from TRetH.

- From the rear, attach the trigger connecting links to the pins on

the segment lever bell cranks and connect the springs.

- Brakes and springs.

- From the front, install the brake levers onto wire 29 (0.108").

The long arm goes on the right, between the keystop levers and the

segment lock lever, and rests against the rear of the large roller

on the segment lever. Make sure that the arm is not caught behind

the small roller on the lock lever. The short arm passes to the left

of the trigger connecting link and helps to hold it onto the bell

crank. Keep the brake lever springs to the top and facing rearwards

over tie rod C.

- Start wires 23 and 24 (0.088") from the left-hand side. The shorter

front wire 23 has a groove at the left which engages with a spring clip

on the second frame plate. (This arrangement was used on earlier

models to provide clearance for the bell, and has been carried over

even though the bell has been deleted). Attach the brake springs to

wire 23, and hang the segment lever springs from both wires to align

with the hooks below. Stand the machine on its left-hand side and

connect the springs to the segment lever hooks. Ensure that any

different springs are returned to their original locations.

- Initial trigger checking.

- Check that the segment lever is held fully upwards against wire 33.

(If not, the key stop levers are probably too far to the left and

caught under the pin on the frame plate). The top of the gear segment

should be about level with the bottom of the hole for tie rod B. Check

that the key tabs on the lock lever stand higher than those on the

segment lever.

- Temporarily install tie rod B and the eccentric adjusting spacers.

Set the spacers carefully to the half-way position, with the high

points all horizontal and facing forward.

- Check that the lower rear tabs of all the triggers are behind the

hooks on TRetV and are not caught above. Check that the crossways

horizontal arms on the triggers are resting on the top of the segment

lever. Check that the left-hand arms of TRetH are sitting above the

vertical arms of the triggers and are not caught behind. Check that the

small horizontal tab at the front of the right-hand arm of TRetH is

resting on the vertical projection on the segment lever and not

jammed beside.

- Check that the pins at the front of the triggers are all in a

straight line horizontally and vertically. The tops of the pins

should be about level with the top of the adjacent frame plate. If any

are out of line, check first that the eccentric spacer is still set

correctly. If necessary, adjust the rest position of the trigger by

carefully bending the horizontal arm which rests on the segment lever

with a suitable tool.

- Take a 4 key (or any suitable flat-ended tool) and press down on

any pair of key tabs near the front of the segment and lock levers.

Check that the front of the trigger moves forward as the lock lever

descends, then lifts upwards until it meets stop wire 17 as the

segment lever starts to move.

- Press down again, and watch the engagement of the left arm of

TRetH with the vertical arm of the trigger. The vertical arm starts

out under the tip of TRetH, then moves forward and clear. Then

simultaneously the vertical arm rotates rearwards and TRetH starts to

descend. The tip of TRetH must end up sitting exactly on top of the

vertical arm of the trigger, with no chance of getting caught behind

during the simultaneous movement. This is the "armed" position.

- Press down again to bring the trigger to the armed position. Hold

this position, then press down slowly on the pin at the front of the

trigger. Watch, listen, and feel for two distinct clicks as the two

trigger retainers drop into position. (This simulates the keystop

disarming the trigger at the bottom of the keystroke).

- Check again that the "feel" and movement of the triggers are

identical in each column.

- When all is correct, insert tie rod G and carefully fit the plain

spacers. Fit the thin spacer and the screw at the left-hand end.

- Remove tie rod B and the eccentric spacers.

- Touch-off bar and column locks.

- Prepare the touch-off bar support assembly 20 and the column

locking hooks. Check that the cross-arms on the locking hooks are not

bent or damaged, and the tiny spring-loaded arms are free to move.

(Excessive force on locked keys will generally bend the cross-arms

before it breaks the segment lever).

- Push the TRetH&V pivot wire 32 to the right until clear of the

leftmost column.

- Feed the touch-off bar support assembly 20 into the large cutouts

near the top centre of the frame plates, with the spring clips on the

left-hand side and the arms facing forward. When fully inserted,

rotate the arms down into the gaps behind TRetV, keeping them in front

of the spring anchor wire 30. Spread the outer frame plates slightly

and engage the pins on the end of the bar with their bearings. Check

that the bar swings freely.

- Push wire 32 back home, through the hole in the left-hand arm of

the support assembly, so as to limit the movement. Attach the spring

3x7x0.2 from the left-hand arm to the tab on the frame.

- Hold the leftmost locking hook with the movable arm at the top

left. Press the segment lever down and hold. Lower the locking hook

down into the column, pass the right-hand arm through the frame cutout,

back up, and hook the tab over the frame plate. Release the segment

lever and insert pivot wire 22 (0.088"). Check that the cross-arm

of the locking hook is behind the fixed hook on the segment lever.

Continue to the end.

- Insert the touch-off bar 31 (1/16" square) and the column lock

retainer 21 (0.088", grooved) into the touch-off bar support arms

from the left-hand side. Engage the spring clips with the grooves

in the wires.

- Push the touch-off bar rearward and check that the locking

hooks swing freely into position under the corresponding hooks on

the segment levers. Release the touch-off bar and check that all the

hooks move clear of the segment levers.

- Key stops.

- Check the loops on the free ends of the long keystop springs and

re-form if necessary so that they are just slightly open. Check the

half-round pins on the bottom ends of the keystops and ensure that

they are still firmly riveted to the arms.

- Start at the leftmost key column. Fit the smaller keystop into the

column with its short right-hand arm over the top of the frame plate.

Engage the right-hand tab on the horizontal arm with the hook on the

key stop lever. The left-hand tab sits above the trigger.

- Turn the larger keystop 90° to the left. Place it over the

first, engage the hook, and feed in wire 13 (0.108") to retain. Check

that the tabs are still properly engaged. Check that the keystops are

free to move and are not jammed against the segment lever.

- Repeat for the remaining columns. Remove the support plate to

install the upper keystop in the right-hand column. Do not replace the

support plate yet.

- Prop up the machine on its back and connect the keystop springs to

the tabs on the frame plates. Use a long wire hook to pull the loop

of the spring up against the tab, and a wider tool to push or pull the

body of the spring into a position where the loop can be slipped into

the hole. Ensure that the loop is fully engaged. Although it looks

impossible at first, the springs can all be connected up in about 10

minutes after a bit of practice.

- Set the machine on its feet. Insert a 4 key in the first column,

between the lock lever and the key stop levers and just forward of

the trigger hanger, and engage it with the fourth set of key tabs

on the long levers. Press the key fully down and check for smooth

operation of the even key stop. Move the key to the third set of tabs

and check the odd stop. Correct as necessary, then repeat for

each column.

- Accumulator interlocks.

- Remove tie rod B and the eccentric spacers.

- Prepare the subtraction cutoff lever, the accumulator latch, the

accumulator locking hook (ALH) and the pinion ratchet reverse lock

(PRRL) for the leftmost key column, and two plain wires 0.088" and

0.0625". If the parts have not been kept in column order it will be

necessary to sort the sub cutoff levers into their original colour

groupings. Attempts to rearrange the coloured buttons later will

result in breakages.

- Hold the subtraction cutoff lever above the active column. Pass

its lower end through the top front cutout in the frame plate to its

left. Move it down and across to the left into the outer (keyless)

column, and engage its right-hand side with the small locating tab on

the right of the frame plate. Insert wire 11 (0.088") to retain.

- Place the accumulator latch onto the end of wire 11, at the left

of the active column. The vertical end passes under the keystop

wire 13 and points upwards at the rear. Push wire 11 in until flush

with the end of the latch. Push wire 12 (0.0625") through the notch

in the subtraction cutoff lever and attach the latch spring

2.8x4x0.18 to wire 12.

- Engage the fork on the rear of the accumulator locking hook with

the pin on the front of the trigger, then lower the ALH down into

position. Push wire 12 into the left-hand arm only, and insert a

spare wire from the right to support the opposite arm.

- Check that the small spring 2.8x3.6x0.22 is securely attached

between the two holes in the central tab of the pinion ratchet reverse

lock. Place the PRRL between the arms of the ALH, with its long arm

downwards on the right. Feed in wire 12 to retain. Draw the spring

forward and attach it to the bridge of the accumulator locking hook.

- Repeat for the remaining columns.

- Accumulators and carry levers.

- Replace tie rod B and the eccentric spacers. Re-set the cams to

the half-way position with their high points facing forward. Check

that all the segment levers are resting against the underside of the

spacers.

- Check all accumulator parts for dirt or damage, and ensure that

the ratchet pawls move freely.

- Assemble the accumulator for the leftmost (overflow) column. This

accumulator has a plain spacer at the right instead of the pinion

ratchet. Place it into position and feed in pivot wire 5 (0.088")

to retain.

- Assemble the accumulator for the next column. Hold the assembly

in tweezers so that the deep cut on the pinion is one tooth forward of

the top. Press down on the rear of the accumulator latch to provide

clearance, then ease the accumulator up into position. Engage the

pinion with the segment rack and feed in the pivot wire. Check the

deep tooth alignment and correct if necessary.

- Continue to the end. Check again that all the segment levers are

fully up and all the deep teeth on the pinions are correctly aligned,

one tooth forward of top.

- Prepare the backstop, backstop spring, carry lever, and latch

lifter for the rightmost column. Check the carry lever very carefully.

Ensure that the roller pivot is still firmly riveted and that the

roller turns freely. Remove any burrs on the three rearward-facing

points so that they can not catch on the lantern wheel. Check that the

three riveted levers all move freely, and that the spring(s) are not

damaged or distorted.

- Start the backstop wire 6 (0.088") from the right-hand side. Place

the backstop in position over the lantern wheel and feed the wire into

the right-hand arm only. Feed in a follow-through wire from the

opposite side to support the left arm.

- Hold the backstop spring with the hooked end upwards at the right

and place the coils between the two arms. Advance wire 6 through the

coils. Note that backstop in the rightmost column has a stronger spring.

- Place the carry lever assembly in position beside the backstop

and support it with the two wires.

- Place the latch lifter between the arms of the carry lever, with

the cut-away section of the hub at the top left. Ensure that the longer

rearward arm sits under the tab on the accumulator latch lever. Advance

wire 6 to the next column and continue to the end.

- Support the front of the machine a few inches off the bench. Press

the top of the backstop spring back and down with a finger, catch the

end from underneath with a fine spring hook, and sit the end of the

spring on the edge of the frame plate. Remove your hook, then push the

end of the spring to the right so that it hooks over the frame. (If you

put the spring in position directly you will have trouble removing

your hook). Ensure that the spring is securely hooked over the frame,

then continue to the end.

- Fit the top front tie rod E and the special formed spacers with the

rolled lip pointing upwards at the front. Ensure that the top arm of

the carry lever is below the rear of the spacer and not caught above.

- Insert the spring retainer wire 8 (0.0625") and attach the

carry lever springs. The springs must come off the top of the tab on

the carry lever, not from the bottom or side. The top loops should be

on the left so that the springs do not rub on the upper arm of the

lever. Lift the spacers hard up against the wire.

- Lift the bottom rear pawl of the carry lever and push it rearward,

so that it passes above the segment lever roller and engages with the

lantern wheel. (Lift the ALH if necessary). Temporarily insert the

intermediate gear shaft 7, which acts as a forward stop for the carry

levers when the segment lever is lowered. Check the the fine torsion

springs on the carry lever are still in position.

- Accumulator and trigger checking.

- While carrying out some of these checks it is necessary to keep the

accumulator latch clear of the accumulator gear. Lift the front of the

latch with a small hook, or press down on the rear end without touching

the trigger. When fully assembled, the latch will be raised

automatically by the latch lifter whenever the rock frame is engaged.

Perform these checks and adjustments carefully, as most of the

mechanism will be inaccessible once the keyplate is installed.

- Insert a No. 3 key in the leftmost column, between the key stop

levers and the lock lever, with the right-hand shoulder above the

third operating tab on the lock lever. Lift the accumulator latch and

slowly press the key fully down. Watch and listen for the trigger

retainer operation as before. Let the key rise very slowly, and check

that the backstop drops over the third lantern wheel bar just as the

segment lever reaches the top of its stroke. Adjust the eccentric

spacer so that the backstop engages reliably every time, with minimum

over-run of the lantern wheel. Check several times to engage with

different bars on the lantern wheel. If larger or unobtainable

adjustments are needed, it is likely that the pinion deep tooth

alignment is incorrect, or the pinions, lantern wheels, and backstops

have been mixed and are no longer paired correctly.

- Make a full keystroke (down and back). Release the accumulator

latch, and check that its forward arm drops fully between the teeth of

the accumulator gear. The gear should not move as the latch engages.

Adjust the eccentric slightly if necessary, then re-check the

backstop operation.

- Partially depress the key so that the pinion ratchet only advances

2 clicks, then let the key rise slowly. Check that the trigger operates

the column locking bar as the lock lever rises. You should hear another

click as the touch-off bar latching lever drops into place. Press down

slowly to complete the keystroke, and check that the column locking bar

resets as the keystop presses down on the trigger, just before the

key reaches the bottom. Check again that the trigger retainers H and V

drop into position at the bottom of the keystroke, with sufficient

excess movement to ensure reliable operation.

- Lift the accumulator latch and push the carry lever rearwards.

Check that it advances the accumulator by one place, and that it

returns fully when released slowly. Repeat 10 times to check every

bar on the lantern wheel. If the lever stops half-way, check for

tight pivots, damaged or mis-placed springs, burred pawls on the

carry lever, or damaged bars on the lantern wheel. If these are all

correct, increase the clearance for the overrun pawl by setting the

segment lever eccentric stop a little lower, then re-check that the

backstop and accumulator latch still operate correctly. There is a

fairly limited range in which all these adjustments will be correct.

- Repeat for the remaining columns. When all columns are working

correctly, tighten the screw at the left of tie rod B to lock the

eccentrics in position.

- Mul/Div control.

- Push tie rod G and wires 17, 18, and 33 to the right until clear

of the leftmost column.

- Fit the touch-off bar master latching lever to wire 33, making

sure that its long rearwards arm is above the touch-off bar 31. The

lever is similar to the the column latching levers in Fig.21 above.

- Put the release plate 14 in position above the keystops, with its

fingers facing upwards from the rear of the shaft. Engage the pinned

ends with the bearings in the outer suport plates, then attach the

spring 3.5x7x0.3 to the keystop wire 13.

- Insert a plain frame spacer into the hub of the Mul/Div lever

assembly and place it in position on tie rod G. Engage the forked arm

into the groove near the left-hand end of the release plate. Push the

release plate rearwards to horizontal and check that pressing further

pulls the Mul/Div lever forward (via the pin next to the forked arm).

Fit the narrow spacer and screw at the left of tie rod G.

- Hold the latch release lever with the straight arm vertical on the

right. Lower the curved arm down into the column and start the trigger

hanger wire 18 into the right-hand side. Attach the spring 3x15x0.2

from the latching lever to wire 18, then feed the wire right through.

Rotate the release lever so that the long curved arm comes up under

the rear of the latch lever, then tuck the forward arm under the tab

on the left-hand end of the release plate 14. Attach the spring

3x15x0.3 from the latch release lever to wire 19 (0.088", crimped on

left, short on later models).

- Attach the spring 3x16x0.4 from the bottom of the Mul/Div lever to

the trigger stop wire 17.

- Fit the error release button shaft 15 to the slots in the top of

the frame plates. Early models have a clip to a frame plate secured by

the second crimped wire 16, and a tension spring 3x28x0.2 to the

keystop wire 13. Later models have two circlips around the shaft 15

and a torsion spring around wire 16.

- Press the Mul/Div lever down and rearwards and check that it

latches under wire 16, then pull it forward to disengage. Push the

touch-off bar 31 rearward and check that the master latch operates to

hold it in position. Press the error release button and check that

the latch releases. Engage the latch again, press down on the release

plate 14 to simulate clearing the machine, and check that the latch

releases.

- Engage the Mul/Div lever. Push the touch-off bar rearward and

check that it does not latch. Press down on the release plate and

check that the Mul/Div lever disengages. (A field service modification

was available so that the Mul/Div lever would remain engaged until

released manually. This involved removing the pin at the left of the

release plate so that the forked arm would not be drawn forward when

the machine was cleared).

- Cross-shafts and right-hand side.

- Fit the short tie rod I with plain round spacers. Fit washers over

the tie rod at each end and firm up the screws.

- Be careful not to over-tighten any of the small tie rods. These

rods are only 5/32" aluminium with a coarse 7/64" internal thread.

There is only 0.023" of metal on each side, which can easily be pulled

apart by over-enthusiastic tightening. A machinist can repair or

replace a broken rod, or a home-made replacement can be cut from

5/32" steel with external threads, nuts, and washers at each end.

Make sure that the replacement rod does not interfere with the

mechanism retainer plates.

- Flip the machine over (front to back), with a suitable support to

keep the subtraction buttons off the bench. Fit tie rods J and K (with

two internal threads) and plain spacers. Replace the two internal feet

and the short spacers in the original columns. Look for the oil stains

on the frame plates to locate the feet, or match the feet with the

impressions in the lining of the base.

- Start tie rod H and fit the formed spacers. The open side of

the spacers faces the baseplate, with the single folded tab pointing

forward. These spacers must be aligned correctly to avoid blocking

the movement of the No. 6 keypieces.

- Stand the machine on its left-hand side and remove the right-hand

support plate. Check that the bearings for the release plate 14 and the

rock frame actuating shaft 2 are still firmly riveted to the plate.

These bearings take a considerable load as the machine is cleared, and

sometimes become quite loose. Repair as necessary.

- Assemble the clearing handle mechanism on the support plate. Adjust

the inner sleeve to provide free movement with minimal side play.

- Place the detaining toggle release bar support 27 in its bearing

in the left-hand suport plate, with the clip at the left-hand side and

the arms facing outwards. Then rotate the bar so that the arms face

straight up into the mechanism.

Arrange the links on the rock frame actuating shaft 2 so that the

triangular bell crank for the shutter reset mechanism sits above the

longer slotted link, as shown opposite. Place the shaft assembly in

its bearing in the support plate, with the links above the shaft and

facing forward. Ensure that the leftmost links are above the front

foot.

Arrange the links on the rock frame actuating shaft 2 so that the

triangular bell crank for the shutter reset mechanism sits above the

longer slotted link, as shown opposite. Place the shaft assembly in

its bearing in the support plate, with the links above the shaft and

facing forward. Ensure that the leftmost links are above the front

foot.

- Place the spacers on all the tie rod ends, matching the heights to

the tie rod nuts and the offsets in the support plate. Later models

have a flat plate with all nuts and spacers 0.25". The spacer with the

reduced outside diameter goes on tie rod H. Fit the interlock L-lever

over this spacer, with the connecting link towards the rear.

- Fit the support plate over the tie rod ends. Check that the outer

rock frame links are above the front foot. Engage the rock frame

actuator shaft, release plate, and detaining toggle release bar with

their bearings and their clearing mechanisms. Check that the support

plate sits flat across the spacers. Fit the large screws and washers

to tie rods A,B,C, making sure that the washers are centred over the

rods. Firm up the screws in rods A,B,C from both sides, then check

that the rock frame actuator and the detaining toggle release bar

still have a small amount of end play.

- Place the machine back on its feet, with a block under the front to

protect the rock frame links. Check that the release bar has a (very)

small amount of end play. Check that the reset arm at the right of the

release plate is aligned with the clearing arm below, and has no chance

of slipping off. Check that the release plate fingers are properly

aligned with the rear ends of the accumulator locking hooks. It may be

necessary to loosen the right-hand side, lift the release plate, and

adjust the hooks and/or triggers sideways to ensure positive engagement.

- When these adjustments are correct, fit the remainder of the screws

and tighten from both sides. Make a full and a short keystroke in

every column (as described under "Trigger and accumulator checking"

above) to check that tightening the frame has not caused anything to

bind or stick.

- Rock frame detaining toggle.

- Stand the machine on its back, with a suitable support to stop it

falling backwards. Assemble the two parts of the detaining toggle and

place in approximate position behind tie rod F in the leftmost column,

with the long link rearwards and above the central tie rod H. Spread

the frame plates and ease the short shaft into the bearing holes 1.

- Place the long link from the detaining toggle between the two tabs

on the left arm of the release bar assembly 27. Insert the plain end of

the release bar 28 (0.088", grooved) to hold the link in place. Push

wire 28 through to the right-hand side and engage the link from the

clearing mechanism. Check that wire 28 is behind the tails of the brake

levers and properly engaged with the clip on the left-hand side.

- Place the short forward link from the detaining toggle onto the

grooved pin on the operating arm near the left of the rock frame

actuating shaft.

- Connect the spring 4x40x0.4 from the detaining toggle to the tab

on the leftmost frame plate.

- Connect the larger spring with the slotted link to the post at the

top centre of the leftmost frame plate. Pull the link forward with a

spring hook and fit the slot onto the grooved pin at the left of the

rock frame actuating shaft, so as to retain the link from the detaining

toggle.

- Fit tie rod F and plain spacers. The leftmost spacer has the

diameter of its centre section reduced from 0.025" to 0.020" to provide

an over-centre stop for the detaining toggle. Fit the rock frame

actuating shaft support plate and short spacer near the centre of

the tie rod - look for the oil stain on the frame plates.

- Place the machine back on its feet, with a block under the front to

protect the rock frame links. Carefully pull the clearing handle

forward, making sure that the rock frame links do not catch on the

frame or the carry levers. Check that the handle moves and returns

freely. Insert a key in any column and check that the detaining

toggle releases.

- Rock frame assembly.

- Check the carry lever locking dogs (rivetted to the rock frame

plates) and ensure that they move freely.

- Assemble the tie rods, frame plates, and spacers according to your

map. Fit the screws but do not tighten yet.

- Place the rear (wide) side flat on the bench with the curved end

plate to the left. Fit the pairs of escapement levers with their short

arms under the clip at the left-hand side. Note that there is a

special pair for the leftmost (overflow) column.

- Fit the toggle lever and zero stop assemblies. There is a narrow

lever at the left, one with a spring clip at the right, and levers

with actuating forks in alternate columns between. If the toggle

levers and zero stops have become separated they are best assembled

on the end of a spare wire held in a vice, as the torsion springs

are quite strong.

- Turn the frame over and insert the locking dog stop wire.

- Close the retainer plates at each end and insert the intermediate

gear shaft 7 (0.108") through the top holes. Hold the frame against

a flat surface and tighten the screws from both ends. Be careful not

to over-tighten. Remove wire 7 and open the retainers. Be careful not

to twist the rock frame during further operations.

- Check that the roller at the front of the carry gear cam turns

freely, then assemble the carry gear, spring, and escapement. Wind

the spring to restore the pre-load found on disassembly, then hook the

escapement arm behind the stop pin on the gear. Fit the assembly into

the frame and insert the pivot wire. It will help keep the parts

together if you assemble them on a short temporary axle (about 5/8" of

1/16" rod) which can be pushed out as you insert the pivot wire.

- Hold the zero stop clear of the carry gear stop pins, rotate the

gear by hand, and check that the escapement wheel follows half a turn

at a time. Close the retainer plates.

- Shutter reset links.

- Support the front of the machine on a suitable block. Push

rearwards on the detaining toggle release bar 28 to release the

toggle. Check that the outer rock frame actuating links are resting

on the front feet and the inner links are hanging below the frame.

- Take the leftmost shutter reset link (the one with the tiny spring

clip) and hold the link vertically, with the curves forward and the

bottom tab offset towards the left. Insert the straight end into the

leftmost (overflow) column, between the left-hand frame plate and the

accumulator gear and behind the accumulator shaft. Fit the remaining

links in alternate columns to align with the rock frame actuating

links below. Ease the links down between the subtraction cutoff lever

and the accumulator latch so that they sit on the accumulator shaft

at the same level as the first. Check that the lower ends of the links

are on the right of the frame plates and not caught in the cutouts.

- Starting from the right-hand side, fit the curved shutter links to

the left of the vertical links, with the tab curled over the top and

the free end facing forward. Insert wire 10 (0.075", narrow groove at

left) from the right-hand side to retain. Engage the clip at the left

with the rear of the groove.

- Rock frame installation.

- Check again that the intermediate gear shaft 7 (0.108") passes

freely through the holes in the top of the rock frame and the

corresponding holes in the main frame plates. Correct any tight spots

by feeding a 7/64" drill bit in from the end and easing the hole on

the side flutes of the drill.

- Check that the formed spacers on tie rod E are hard up against the

carry spring wire 8. Loosen the tie rod and correct as necessary.

- Support the front of the machine about 100mm (4") off the bench.

Push rearwards on wire 28 to release the detaining toggle. Press

rearwards on the front arms of all the accumulator latch lifters so

that the rear arms stick in position up under the latches.

- Cut a piece of 1/16" rod or wire to slightly less than the width

of the rock frame. This will be used as a temporary locking wire to

keep the mechanism at zero during installation.

- Stand the rock frame on the bench with the forked levers at the top

and the carry gears behind. Push the forked end of the right-hand

toggle lever rearward against the tie rod, then draw the carry gear

upwards until the spring is under tension. Lift the toggle lever

so as to engage the zero stop, then insert the temporary wire through

the hole in the toggle lever as shown in the illustration opposite.

Continue to the end.

- Check that all the zero stops are standing about half-way under

the stop pins on the carry gear. Serious misalignment can be corrected

by carefully bending the small spring-loaded tabs between the zero

stop and the toggle lever.

- Do a final check that all the carry gears are still under tension,

the carry levers are still engaged with the accumulators, the fine

torsion springs on the carry levers are still in position, and the

latch lifters are still rearwards.

- Hold the rock frame at each end and carefully insert the lower

arms under the carry levers. Rotate the bottom rearwards until the

leftmost escapement lever sits over the toggle link attachment point,

as shown for removal. Let the rock frame sit in this position while

you place the intermediate gears into the gap at the right of the

carry gears. The recessed side of the gear faces to the left. (It is

not strictly necessary to put the intermediate gears in position at

this stage, as they can be installed later from the top. However,

when it becomes necessary to remove and replace the rock frame for

maintenance the top access will be blocked by the numeral wheels.

This slightly more complex procedure can be used in both cases).

- When the rock frame is sitting correctly, the top will swing easily

under the spacers on tie rod E. Difficulties may be caused by

incorrect assembly of the tie rod end fittings, the lower arms

fouling on the actuating links, the toggle links fouling on the

attachment rivets, the carry gear fouling on the forward arm of the

carry lever, or the temporary locking wire being too long.

- When the rock frame passes under the tie rod, rotate it inwards

and upwards and move it further left to engage the lateral locating

flanges on the top tie rod with the frame plates. Insert pivot wire

7 (0.108") to support the rock frame, or use temporary 7/64" pins

from each side.

- Check that the rock frame swings freely back and forth on the

pivots. Push the rock frame rearwards and check that all the

accumulator latches lift slightly. If any fail to move, remove the

pivots, draw the rock frame forward, and push the latch lifter down

behind its operating pin. Replace the pivot wires and check again.

- Pull the rock frame forward and connect all the toggle links and

levers to wire 4 (0.075", with a ring at right-hand side). Remove the

temporary locking wire.

- Remove the temporary pin, stand the machine on its left-hand side,

and connect up the rock frame actuating links. Starting at the top,

engage the shutter reset link with the pin at the rear of the

triangular bell crank. Engage the pin on the slotted actuating link

with the fork on the rock frame toggle lever. Align the hole in the

bell crank with the slot in the link and feed the supporting wire 3

(0.088") through both. Rotate the actuating shaft slightly to align

the holes. It gets easier after the first couple are in place. The

wire should pass easily through all the links without forcing.

- Attach the two helper springs from the toggle wire 4 to the formed

spacers on tie rod A. Loosen the tie rod and adjust the spacers so

that there is a slight tension on the helper springs.

- Rock frame toggle testing.

- Place the machine back on its feet and replace the temporary pivot

pin. Carefully operate the clearing handle, freeing the shutter links

if they become caught. Check that the rock frame moves forward and

that the detaining toggle locks over-centre. Check that the clearing

handle still returns freely.

- Push rearwards on wire 28. Check that the detaining toggle releases,

the rock frame snaps down and rearwards, and the shutter reset wire

rises evenly about 5mm. Free the curved links if they become caught.

The rock frame movement must be quick and positive.

- Look in from the left-hand side and check that the large carry gear

is fully engaged with its accumulator gear.

- Clear and release the rock frame again. Examine the small toggle

links 4 closely to ensure that they are all fully over-centre. If

either end of pivot wire 4 can be pushed down further it usually means

that the rock frame is twisted. Correct as necessary so that the rock

frame toggles all engage quickly and fully when the detaining toggle

is released.

- If the rock frame does not engage fully, the problem may be in

the actuating links or in the engagement of the gears. The zero

position of the carry gear depends on the zero stop levers and the

zero studs, which may be loose or damaged. The zero position of the

accumulator gear depends on the eccentric spacer setting and the

alignment of the pinion deep tooth. Mis-alignment can cause a pair of

gears to clash tip-to-tip and prevent the rock frame from engaging

properly. Locate and correct any errors before proceeding.

- Readjust the helper springs so that they are still under a slight

tension when the rock frame is fully engaged.

- Numeral wheels and shutters.

- If the machine has coloured numeral wheels, arrange them in order

to match the keytops. Note that the wheels are not all the same, due

to the shorter hubs in the columns with the shutter reset links.

- Clear the machine. Starting at the left, place the shutter assembly

inside the numeral wheel and ease it into position from the front. Pass

the long arm (the sub cutoff latch) through the frame and up against

the pin on the sub cutoff lever. Pull the assembly forward and arrange

the short rearward arm in front of the shutter reset wire 10.

- Start the numeral wheel pivot wire 9 (0.0625") from the left and

engage it with the curved shutter link. Align the wheel and shutter

and feed the pivot wire through. Check that the wheel spins

freely - ease the frame plates if necessary.

- Connect the stiff spring from the sub cutoff lever to its latching

lever. Pull the loop forward with a spring hook and twist the end into

the hole with a pair of fine bent-nose pliers or similar. Ensure that

the loop is properly formed and fully engaged.

- Fit the sub cutoff latch release lever flat against the right-hand

side plate, with the lower offset arm to the right of the carry lever

spring. Engage the forked end with the locking dog stop wire in the

rock frame (immediately below the top tie rod), then ease the top end

rearwards past the shutter operating arm. The arm should then drop

freely into position without binding or sticking.

- Install the remainder of the numeral wheels, shutters, and latch

release levers.

- Hold the rock frame in position and swap wire 7 to the left and the

temporary pin to the right. Set the leftmost numeral wheel to zero,

lift the intermediate gear so that it engages with both the numeral

wheel and the carry gear below, and feed in the pivot wire. The hollow

zero should be centred over the silver section of the shutter behind,

and just slightly forward relative to the raised section on the

frame plate.

- Push the intermediate gear to the left, then pull back the pivot

wire to leave a gap between the gear and the frame plate to its right.

- Take the shutter release lever and check that it is not bent or

twisted. Check that the roller turns freely, and that the fine torsion

spring is properly located in its groove. Wind the spring clockwise

so that both ends are in front of the side tab, hold the spring with

your thumb, then insert the left-hand arm and roller into the gap in

front of the intermediate gear hub. Slide the arm downwards and

rearwards into position. When you have to let go of the spring it

should stop on the top tie rod, then finally come to rest in the notch

at the right of the sub cutoff latch release lever. Align the levers

and feed in the pivot shaft from the left. Continue to the end.

- Insert a key (eg 3) in the leftmost column, between the key stop

levers and the lock lever, and above the operating tabs on the lock

lever. Make several full strokes of the key and check that the

mechanism operates as expected. Check that the tens-carry proceeds

into the next column. Make short strokes and check the operation of

the touch-off bar, column locks, and release button. Repeat for the

remaining columns. Check thoroughly, as the trigger and eccentric

spacer adjustments will be inaccessible after the keyplate is fitted.

- Clear the machine and check that all the zero shutters are closed.

Press a key in the rightmost column and check that only the rightmost

shutter opens. Clear and repeat in each column, checking that all

and only the shutters to the right of the column will open. Adjust

the cascaded shutter levers as necessary so that they trip and

reset correctly.

- Clear the machine and use a 9 key to enter 999...999. Press the

rightmost subtraction cutoff button and check that it latches

rearward. Add 1 in the rightmost column. Check that the numeral wheel

advances to 0 without producing a carry, and that the cutoff button

springs forward. Repeat for the remaining columns.

- Press all of the subtraction cutoff buttons rearward so that they

latch in position, then check that they are released when the clearing

handle is operated.

- Keyboard.

- Check the locating tabs under the keyplate, and the places where

they engage with the tops of the frame plates. Any distortion or

misalignment can make it difficult to insert some of the keys and

may cause the columns to jam.

- Engage the front of the keyplate under the tabs at the front of the

frame plates, then lower the back. Look in from the rear to check that

the locating tabs are properly engaged. Check that the plate sits flat

all round. Insert two retainer wires (with right-angled ends) from the

left, through the notches in the top of the leftmost frame plate.

Insert the third retainer at the right-hand rear of Sterling (or

ex-Sterling) machines. Leave the end of the central wire outside the

leftmost frame plate, so that it can not interfere with the touch-off

bar support.

- Prepare the keys in their colour groups and drop them into the

keyplate. The hooks at the bottom of the keys should be flat, but

resist the temptation to straighten the 1 keys. The bends are

deliberate, to provide clearance from the upper keystop.

- Prepare the keypieces and graduated springs. Springs for rows 1

and 2 are 0.028" diameter, 3 and 4 are 0.0265", 5 and 6 are 0.025",

and 7, 8, and 9 are 0.023". Wear eye protection while handling the

springs.

- Support the machine vertically on its back. Start at the bottom

left (as you look at the underside) and check that the 9 keystem passes

between the key-stop levers and the segment lock lever. Engage the

right-hand leg of the keypiece in its slot, fit the hole over the

keystem, then engage the left-hand leg. Place a finger over the coil

of the spring (to stop it flying off), then hook the tail of the

spring under the tab near the left foot. Push the spring fully to the

left on the supporting pin so that the coils can not work loose.

Proceed left to right across the columns, then upwards, one row

at a time.

- With the machine still vertical, press every key and check for any

problems. The keypieces are quite soft and are easily bent out of

shape (and back again). Make full keystrokes and check for keypieces

that rub against their neighbours or adjacent keystems. Make short

keystrokes, moving only the lock lever, and watch carefully for keys

that do not return fully. This problem is usually due to the keypiece

holding the keystem too far to the left, causing the key stem to bind

on the horizontal flange on the frame plate. Straighten the keypiece

or adjust its left foot to correct. Keys and keypieces can be removed

individually - it is not necessary to disassemble the entire

keyboard. Problems can also be caused by incorrect fitting of the

keyplate so that the locating tabs distort the frame plates and cause

the keys to bind. When all seems correct, place the machine back on

its feet and check again.

- Check the adding, carry, and duplex operation by adding all the

numbers on the keyboard, 3 at a time. Start with the leftmost three 9s,

then the 8s, and so on down the column, then the next three columns,

etc. The result should be 499...995. Add 1 five times and check that

the ripple carry proceeds quickly and smoothly across the whole

register. Test extensively before refitting the casing.

- Casing.

- Cut new rubbers (if necessary) for the locating lugs on the

baseplate, and fit a new tranparent window to the top cover. Repair

any bent or damaged decimal indicators.

- Invert the machine and set it down on a soft cloth. Fit the

baseplate with 4 screws through the rubber feet. Set the machine

down on the base.

- Fit the mechanism wire retainer plates with 3 screws each side.

- Fit the top cover, lay the machine on its side, and fit the

small screws around the edge of the base. Note that there is

very little clearance between the top cover and the back of the

segment levers, to the extent that any damage to the cover or to the

sound deadening material can cause the segment levers to bind. Check

the operation of each column after fitting the cover, then fit the

control buttons.

Problems in assembly.

Many of the potential problems have been addressed in the

relevant sections of the notes, but there are plenty more things

that can go wrong. Problems are much more likely if the parts have

not been kept in column order. Here are a few of the more subtle

problems that may result from errors or oversights in assembly:

- A column usually works but sometimes blocks, especially if operated

slowly. This is usually due to friction or interference preventing a

key from rising fully. The key must rise right to the top of its travel

in order to reset the trigger and release the pinion ratchet

reverse lock. Likely causes are:

- keypieces rubbing together, or holding the key too far to the left

- a mis-aligned spacer on tie rod H preventing the No 6 keypiece

from rising fully

- keystems not passing freely between the keystop and lock levers

- incorrect engagement of the keyplate locating lugs, causing

distortion of the frame and binding of the keystems.

- A column was working, but is now blocked. This may be due to a

spacer on tie rod E being knocked out of position while handling the

machine, so that the rear edge of the spacer fouls against the

intermediate gear. It can also be due to the latch lifter not being

properly engaged with the operating pin on the rock frame, so that

the intermediate gear catches on the edge of the cut-away section

of the latch lifter hub.

- A column has keys 2 to 9 blocked, but the 1 key operates correctly.

This is caused by the rear of the 1 keystem pressing against front edge

of the upper keystop and holding it engaged with the segment lever.

The segment lever can only move down as far as the first stop, which

is sufficient for the 1 key but not for any of the others. Remove the

1 key and carefully increase the curvature - concave side towards

the rear.