Overview

Overview

The "roller" from which this instrument takes its name is a development of the wooden cylinder or barrel that has been used to store music for mechanical organs and musical clocks since the 1700s.

The musical notes were traditionally represented by wire bridges or staples, which were formed by hand according to the length of each note and inserted at the correct location around the circumference of the barrel. As the barrel was turned, the projections operated a valve mechanism to admit air into the musical pipes or reeds.

In 1884 the Autophone Company of Ithaca NY developed a system for representing longer notes by a succession of closely-spaced pins rather than a continuous bridge. This enabled the barrels to be pinned by automatic machinery rather than by hand, which in turn enabled the mass-production and mass-marketing of "Roller Organs" in a variety of models and sizes. The smaller instruments were cheap, simple, and surprisingly effective, and were produced in the hundreds of thousands from the mid-1880s to the 1900s.

Over a thousand different rollers were produced, containing a broad selection of religious, military, operatic, and music-hall tunes that were popular during the 1880s and 90s. For a typical example, listen to Roller No. 23, "Where is my boy tonight" (MP3 file, 78kb), played on an original "Gem" roller organ.

Overview

Overview

The "Gem" was the smallest, cheapest, and most popular of the roller organ range.

It is basically a 20-note suction-operated reed organ in a light wooden table-top case. It measures 14-1/2" wide, 12" deep, and 8" high, and weighs 6-1/2 pounds.

The roller, drive mechanism, and pallet valves are mounted on cast-iron brackets on the top front section of the case. The brass reeds are mounted on the inside of the sloping panel, directly behind the pallets. The pumping bellows or feeders are mounted in the lower section of the case, with the reservoir at the top rear. The rear section of the reservoir is covered with black rubberised "bellows cloth", and moves up and down as the instrument plays.

The roller

The roller

The roller is a solid wooden cylinder measuring (approximately) 6-3/8" long and 1-3/4" diameter, with a circumference of 5-1/2". There is a central mounting hole with a metal bushing at each end, and an offset drive hole at the left-hand end. There is an instruction label at the drive end, and a label with the item name and number at the other. There were over a thousand different rollers available.

The pins are about 0.036" diameter and 0.270" long, and stand 0.100" above the surface of the roller. The pins are spaced on 0.050" (approx) centres, giving about 110 pins per revolution. The illustration shows how notes of varying length are formed from a succession of identical pins.

The roller makes three complete turns per tune, with the pins arranged on a spiral path of 0.100" pitch. The physical length of each tune is thus 16.5 inches or 330 pins. The playing time is about 40 seconds, giving an effective "roll speed" of only 2 feet per minute and a time resolution of 8 pins per second. The mechanical alignment needs to be very precise at this speed, as timing errors from bent pins or pallets are very noticeable.

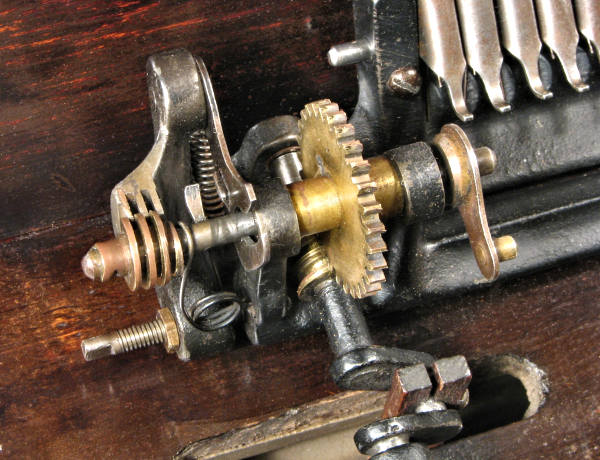

The drive mechanism components

The drive mechanism components

The roller organ has an ingenious drive mechanism that is both simple and effective.

The main component (top) is the cast-iron "key frame" which is attached with two screws to the sloping front panel of the instrument. The pallets or keys are mounted on the central horizontal rod.

The "roller frame" (bottom) is mounted between the two horizontal pivots at the lower front of the key frame, so that it can swing forward to disengage the roller from the keys. The roller is held between the two short horizontal shafts and is driven by the arm at its left-hand end. The springs on the support shafts push the roller towards the left, but allow it to travel 3/10" to the right as the tune progresses (driven by the worm at the far left-hand end).

In the centre of this view are the crankshaft (which drives the roller shaft and the feeders), the outer bearing block, and the winding handle.

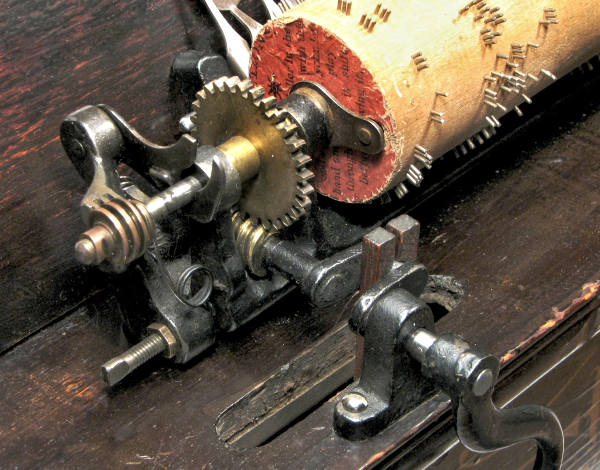

The drive mechanism assembled

The drive mechanism assembled

The crankshaft carries the winding handle (lower right), the outer support bearing, the crank and connecting rod to drive the feeders, and the worm gear which drives the pinion on the roller shaft. The inner end of the crankshaft is supported by a plain bearing in the key frame. The pinion has 28 teeth, so the cranking speed to complete 3 turns of the roller in 40 seconds is a comfortable 125RPM. (The handle rotates clockwise and the roller anti-clockwise in this view).

The worm gear at the end of the roller shaft (centre left) engages with a similar arrangement cast into the end of the key frame, so that it gradually pushes the shaft to the right by 1/10" for each turn. A slotted keyway allows the shaft to slide through the driving pinion.

The roller frame must be positioned accurately fore-and-aft so that the pins engage with the keys to the correct depth (about 0.040"). The positioning is controlled by the small forked arm (or hook) which is pivoted at the upper left-hand end of the key frame. The arm is spring-loaded upwards, locating the roller shaft securely in a notch in the bottom of the fork. Pressing down on the arm cams the shaft out of the notch and pushes it forwards, moving the roller and pins clear of the pallet keys.

The release mechanism

The release mechanism

At the left of this view is the spiral-feed worm, engaged with its mating (E-shaped) section on the key frame. To the right of this are the forked arm and spring, which hold the roller frame inwards while the tune is playing. Note the small tab formed on the flat side of the forked arm (next to its coil spring).

In the position shown, the roller shaft has almost completed its first turn and has travelled 1/10" to the right, as indicated by the gap now visible between the roller drive arm and the frame. The spiral-feed worm acts against the pressure of the return springs at either end of the roller frame.

After two more turns, the flattened pin attached to the roller shaft (to the right of the worm) reaches the tab on the forked arm, just as the tune comes to its end. With another turn of the crank, the pin presses downwards on the arm, which in turn pushes the roller frame forward and clear of the keys. This action also disengages the feed worm from its mating section, so that the roller immediately springs back to the left until the drive arm stops against the roller frame. The forked arm then pulls the roller frame rearward and engages the driving worm, ready to start again. Multiple verses of a song or hymn can be played continuously just by continuing to crank.

It is important that the tensions of the return springs and the forked-arm spring are properly balanced so that the lengthwise motion is completed before the roller frame is pulled rearward. With the drive arm in its home position, the roller frame can be adjusted sideways with the pivot screws (lower left) to ensure that the feed worm re-engages cleanly.

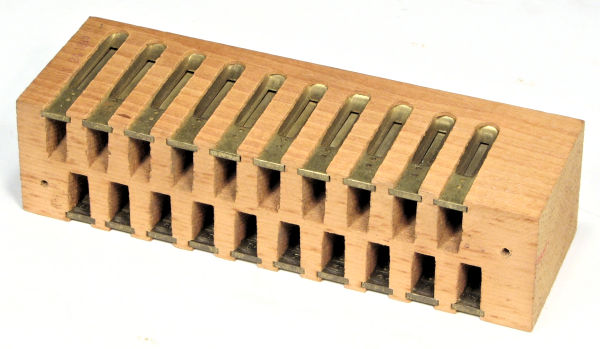

The pallet valves

The pallet valves

The keys or pallets are formed from 0.040" sheet metal and are mounted on a 5/32" rod attached to the key frame. The upper ends have pads of felt and leather which provide an air-tight seal around the openings in the reed board. The pallets are held closed by light springs on the pivot rod.

The lower ends of the keys are bent upwards to engage with the pins on the rollers. The pins push the keys about 0.040", which is amplified by the lever arms into an appreciable movement at the pallets. The keys oscillate slightly as a succession of pins passes, giving a tremolo effect to the longer notes.

It is important that the tips of the keys are perfectly in line both horizontally and vertically to avoid audible timing errors.

The tips of the keys are narrowed to about 0.085" so that they can pass along a row of pins without fouling on the rows on either side. Bent pins, distorted rollers, or excessive side play can easily cause trouble. The keys need sufficient side play to ensure their free movement, but there is only about 0.040" end-to-end clearance available in total.

Note that the sideways positioning of the roller relative to the pallet key tips is controlled by the distance and the angle between the feed worm and the roller drive arm. These dimensions are set when the drive shaft is assembled, and are not easily adjusted in service.

The reed block

The reed block

The music is produced by a set of 20 brass reeds, which are mounted in a wooden block attached to the inside face of the sloping front panel, immediately behind the pallet valves. Air enters through the slots in the front face when the pallets are lifted, passes through the reeds into the reservoir, and out through the feeder bellows underneath.

The reed block measures 1-3/4" high by 7" long, and is machined from a solid piece of timber. There is no soundboard in the usual sense - most of the sound is radiated directly from the reeds and through the pallet openings. There is no provision for controlling the volume.

The lower notes are located in the upper section of the block, so that the greater leverage of the longer keys will give a greater opening distance and a less-restricted air flow.

The reeds

The reeds

The Gem uses conventional "American organ" reeds with standard frame dimensions (0.420" wide by 0.100" thick). The reeds have relatively flat tongues and produce a strong sound.

The musical scale encompasses 20 selected notes over 3 octaves. All instruments using the same-size rollers used the same scale, but the actual key and pitch often varied.

This instrument sounds from D3 (MIDI note 50) to A5 (MIDI 81),

although the reeds are labelled a whole-tone higher. The playing

notes are:

D G A B C C# D E F# G G# A B C C# D E F# G A

The instrument is still reasonably in tune at A = 430Hz.

Note the date stamp (JUN 24 1899) on the end of the reed block.

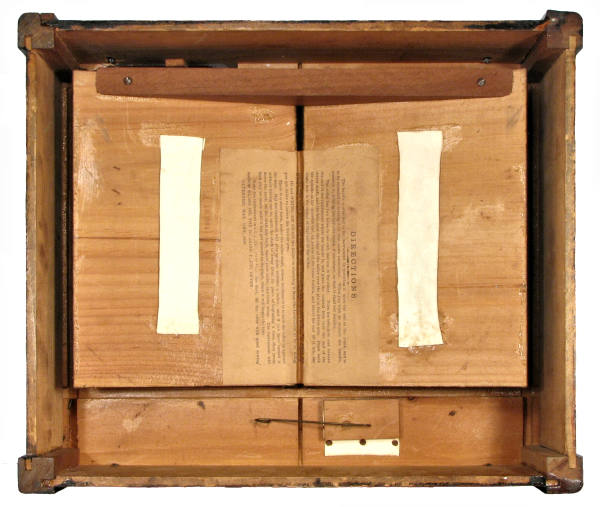

The feeder bellows

The feeder bellows

The underside of the Gem organ contains the two feeder bellows, each measuring 8" by 6". The two feeders are interconnected by the wooden bar at the top (front) so that they open and close alternately. The bar is attached to the crankshaft by a light wooden connecting rod. The crank throw is about 1-1/8", and the bellows travel is about 1-3/4". The white strips are sheepskin flap valves which seal the exhaust ports in the bellows boards. The original instruction sheet is still pasted across the two boards.

At the lower right-hand side is a small relief valve, which opens to prevent damage if the suction pulls the reservoir fully closed.

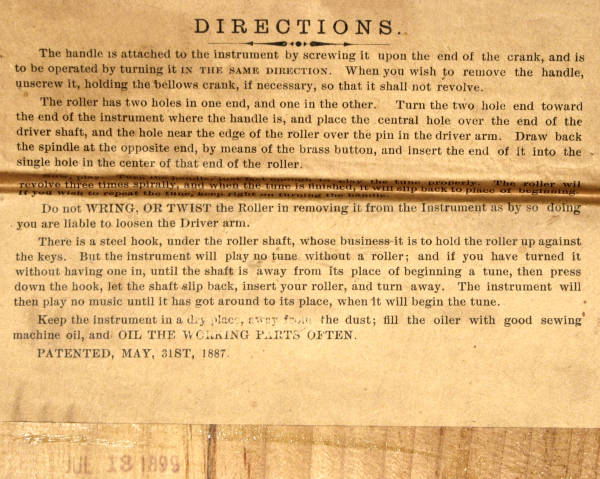

The instruction sheet

The instruction sheet

The instruction sheet attached to the underside of the Gem organ gives a very clear and straightforward description of the operating procedures.

Note the date stamp (JUL 13 1899) on the bellows board below the label.

The "Roller Organ" patents

The "Roller Organ" patents

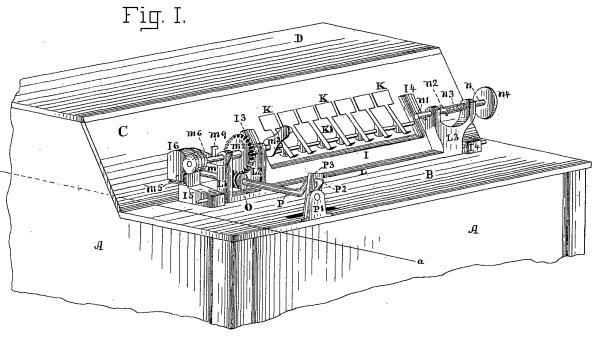

US Patent 322390, which is referenced on the labels of many of the rollers, was submitted by Henry B Morris of Ithaca NY on May 1 1884, and assigned to The Autophone Company of the same place. It describes the method of representing notes by a succession of closely-spaced identical pins, arranged in a spiral around a wooden cylinder. The patent was granted on July 14 1885.

At the same time, Morris submitted a separate application for a method by which the rollers could be "prepared automatically by suitable machinery".

A patent application for a "Mechanical Musical Instrument" was submitted on behalf of The Autophone Company by Morris, Tisdel, and Labar on September 21 1886. It was granted as Patent No. 363841 on May 31 1887, the date referenced on the instruction sheet above. The mechanism shown in this Figure 1 (from the patent drawings) is identical in principle to that of the Gem organ described above.

Having secured patents on the rollers, the pinning machinery, and the playing mechanism, the Autophone Company was able to mass-produce its Roller Organs in a variety of styles and models. The example used in the patent description is a larger instrument in a floor-standing cabinet, driven by a foot-treadle rather than a hand crank, and operating on pressure rather than suction.

Resources for further information

Resources for further information

The late Todd Augsburger from the USA developed a web site at www.rollerorgans.com which is devoted entirely to Roller Organs. The site includes illustrations of many of the other models, and a full listing of all of the known rollers.