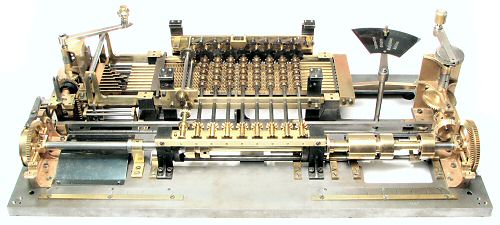

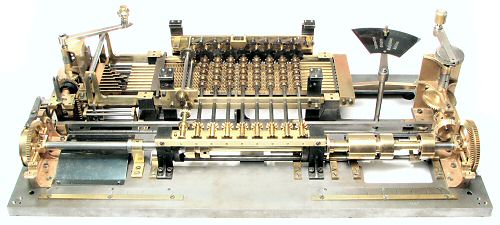

General arrangement.

General arrangement.

The Millionaire calculating machine is an excellent example of late 19th-century engineering technology. Its construction draws on elements of two Swiss specialties - clockwork and music boxes - with more than a hint of the steam engine. The machine is built mainly of cast iron and brass, using metric dimensions and standard metric screw threads. The completed mechanism weighs over 30kg, and contains over 2500 manufactured parts.

General arrangement.

General arrangement.

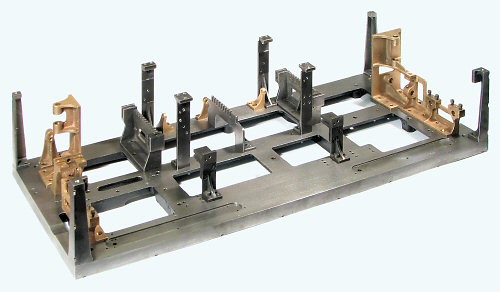

This view shows the general arrangement of the machine with the keyboard and carriage removed.

The racks are mounted left-to-right at the centre rear of the machine, with the cross shafts at right angles above them. There are ten racks, and one cross-shaft for each slider or keyboard column. The carriage register travels right-to-left above the differentials near the centre of the machine.

The multiplier body and its controlling mechanisms are mounted along the left-hand side, with the main drive mechanism at the right. The camshaft across the front controls the sequencing of the machine operations, according to the setting of the Regulator.

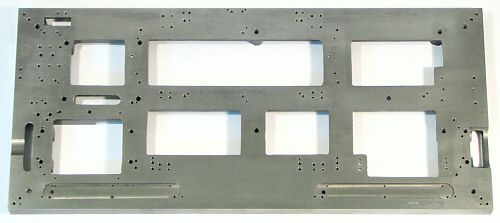

The bedplate.

The bedplate.

The mechanism is built on a cast iron bedplate which measures 638 x 276 x 18 mm. The casting has been planed flat on all the external surfaces using a straight-cut shaping machine. The bedplate alone weighs over 6kg.

There are over 170 plain and tapped holes in the top surface of the bedplate for dowel pins and metric machine screws.

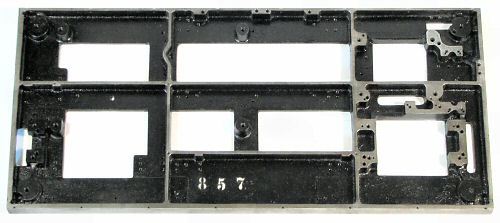

The bedplate under side.

The bedplate under side.

The webs and flanges of the bedplate are generally 4 to 6mm thick, with mounting bosses in the corners and near the centre. There are additional cut-outs and mounting points on the under side of the bedplate for the motor drive and its control mechanism (when fitted).

Note the row of 8 small holes drilled and tapped at 45° into the corner of the bottom flange. These attach the trim strips which retain the side panels on the metal-cased machines.

The mechanism brackets.

The mechanism brackets.

This view shows the major brackets and pillars which support the components of the Millionaire mechanism.

The brackets are machined from brass and iron castings, and are attached to the bedplate with cheese-head screws and dowel pins. There are no flat or spring washers anywhere in the machine.

Casting detail.

Casting detail.

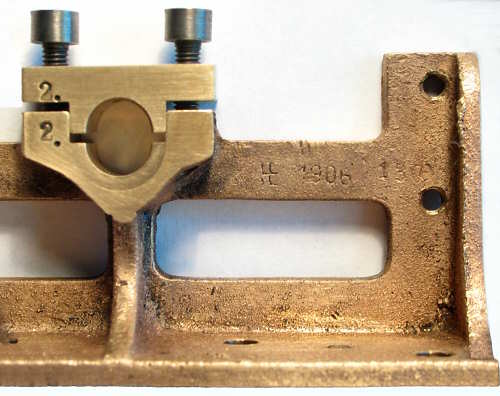

This left-hand camshaft bearing is a typical example of the brass sand castings. There is a stylised "HE" and the date "1906" cast into the upper web. (This is not the date of manufacture of machine number 2968 - see the note at the end of the Racks and Drive Train section following).

Most of the major components of the Millionaire are stamped by hand with the last two digits of the machine number. Similar components (including bearing caps, racks, and cross-shafts) are generally numbered in order. Dots are used to mark the left-hand end of symmetrical items, the larger end of tapered pins, and to provide timing marks on all the gears.