Nylon toothed pulley repair.

Nylon toothed pulley repair.

Nylon toothed pulley repair.

Nylon toothed pulley repair.

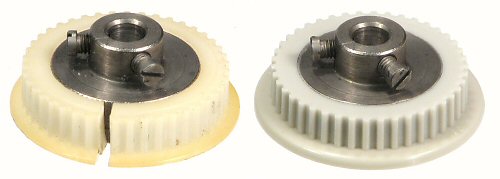

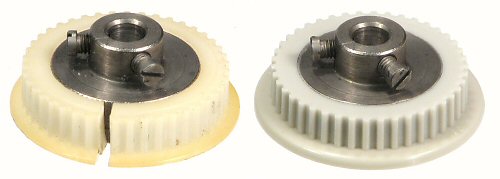

The impression roller drive uses a nylon toothed pulley moulded over a steel hub, and a polyurethane timing belt. Both of these components can be expected to have failed with age, leaving the printer (and hence the entire calculator) inoperable. The nylon pulley shrinks onto the rigid hub and eventually splits, while the polyurethane belt de-polymerises and disintegrates.

Repairs can be made on a lathe by boring out the centre of a standard 40DP 42T acetal or Delrin timing pulley, and fitting the rim onto the original hub. The new 40DP drive belt should have 60 teeth. The replacement items are readily available from engineer's or "small parts" supply houses.

Replacements for the two round drive belts for the keyboard and printer can be made from bulk lengths of 3mm O-ring material from the same source. Bearing service companies can cut and splice O-rings to any length, but quite satisfactory drive belts can be made in the home workshop with scissors and cyanoacrylate adhesive (super glue).